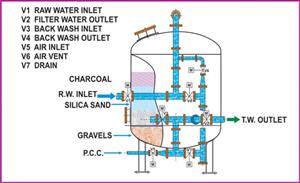

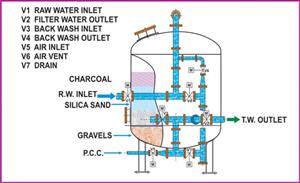

Filtration

The process of filtration involves the flow of water through a granular bed, of sand or another suitable media, at a low speed. The media retains most solid matter while permitting the water to pass. This type of slow filtration over a granular bed is generally known as slow sand filtration. It is the oldest method of filtration but still widely used in municipal water treatment plants & for industrial application as well.

More modern filtration systems use carbon as the main constituent material of the filter. This carbon is compressed into a solid block form, as opposed to the more loosely structured, granular, sand filters. Such filters often include other media substances, in addition to the compressed, solid carbon. This type of water filter is known as a multimedia filter. These filters clean water through both physical and chemical processes. Physically, they perform the same function as slow sand filters, blocking the passage of unwanted materials with molecular structures that are larger than water. Chemically, the carbon or multimedia filters perform an added filtration function.